APPLICATION

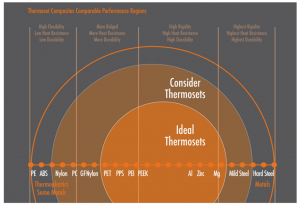

Thermosets can be used in several environments to serve unique markets. They are the strongest solution in terms of fighting against corrosive environments, reduced connectivity in electrical environments, reduced absorption/vibrations in audio environments and provide strength to environments that require less weight.

Cornerstone composites helps you determine the strongest solution for your market.

Cross linking is the key. Thermoset materials are stronger due to the three-dimensional network of bonds called cross linking. As shown in our company’s identity, molecules are locked or set into place creating a strong bind of material that can withstand heat and stress.

THERMOSET COMPOSITES

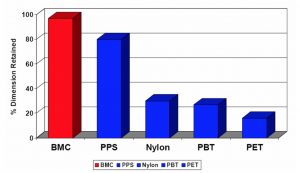

What are they? Mixtures of polymer resins, catalysts and reinforcement Materials react and cross-link when exposed to thermal energy, hence – “thermoset”. Thermosets are permanently solidified upon cross-linking. While thermoplastics can be melted, solidified and melted again with heat cycles, thermosets are permanently solid. So, thermosets are well suited to high temperature environments; thermoplastics are not. Thermoset materials get their unique properties from the formation of three-dimensional covalent bonds between the molecules – “cross-linking”. Thermoplastics exhibit molecule-to-molecule bonds that are largely electrostatic attractions and entanglements.

THERMOSET COMPOSITES

- High Stiffness

- High Strength

- Structural Aesthetics

- Dimensional Stability at Elevated Temperatures

- Low Creep at Elevated Temperatures

- Dielectric Applications

- Chemical Resistance

- Longer Tool Life Compared To Die Cast

- Lower Cost Than Engineered Thermoplastic

- Lower Cost Than Die Cast Metals

Cornerstone Composites – Production Machines Vienna Ave Plant

| Machine# | Tonnage | Main Ram Type | Transfer Ram | Platen Size | Max Mold Heigh |

|

101 |

300 |

Top |

None |

41 X 30 |

39 |

|

102 |

350 |

Bottom |

Top |

40 X 30 |

35 |

|

103 |

400 |

Bottom |

Bottom |

32 x42 |

16 |

|

104 |

300 |

Bottom |

None |

31 1/4 X 31 |

41 5/8 |

|

105 |

200 |

Bottom |

Top |

30 X 24 |

35 |

|

106 |

250 |

Bottom |

Top |

24 1/2 x27 |

33 1/4 |

|

108 |

400 |

Bottom |

None |

28 x48 |

45 |

|

109 |

200 |

Bottom |

None |

27 3/4 X 13 |

35 1/4 |

|

112 |

200 |

Bottom |

Top |

24 x26 1/8 |

36 1/2 |

|

114 |

70 |

Top |

Bottom |

21 1/2 X 19 1/2 |

25 |

|

115 |

70 |

Top |

Bottom |

21 1/2 X 19 1/2 |

25 |

|

116 |

600 |

Bottom |

None |

48 x42 |

41 |

|

117 |

150 |

Top |

Bottom |

27 1/2 X 24 1/2 |

33 |

|

118 |

192 |

Top |

Top |

24 x26 |

32 |

|

119 |

150 |

Top |

Bottom |

27 1/2 X 24 1/2 |

33 |

|

120 |

300 |

Top |

Bottom |

28 X 32 |

37 1/4 |

|

121 |

70 |

Top |

Bottom |

21 1/2 X 19 1/2 |

25 |

|

122 |

350 |

Top |

Bottom |

34 X 30 |

40 1/2 |

|

124 |

500 |

Top |

Bottom |

48 1/2 X 42 |

54 |

|

128 |

350 |

Top |

Bottom |

34 X 30 |

38 |

|

201 |

260 |

Injection |

None |

34×34 |

44 |

|

301 |

99 |

Injection |

None |

14 1/8 x17 |

28 1/2 |

|

302 |

175 |

Injection |

None |

26 1/2 X 26 1/2 |

27 1/2 |

|

305 |

300 |

Injection |

None |

43 1/2 X 38 |

42 |

|

8 |

150 |

Top |

None |

48 x45 |

67 |

|

9 |

150 |

Top |

None |

60 x48 |

67 |

|

10 |

150 |

Top |

None |

60 x48 |

67 |

|

11 |

150 |

Top |

None |

50 x42 |

67 |

|

2 |

450 |

Bottom |

None |

42 x42 |

30 |

|

3 |

220 |

Top |

None |

71 X 48 |

69 |

|

6 |

350 |

Top |

None |

90 x60 | 74 |

|

4 |

150 |

Top |

Bottom |

27 X 23 1/2 |

31 |

|

5 |

80 |

Top |

Bottom |

19 X 26 |

26 |